BUSINESS DECISIONS ARE ONLY AS GOOD AS THE INFORMATION USED TO MAKE THEM.

When a regional manufacturer entered a higher stakes game on a Fortune 500 playing field, the old playbook had to be updated with faster, integrated data.

When a regional manufacturer entered a higher stakes game on a Fortune 500 playing field, the old playbook had to be updated with faster, integrated data.

Midlab is the science of clean beyond the surface with a global reach in manufacturing and distribution of made-to-order cleaning solutions that are among the best of private labels and brands. Everywhere you go in life, Midlab helps keep your world safe, sparkling clean, and protects you from what you touch. But their data was “dirty,” and that required a cleansing solution that would touch every aspect of the business.

“The level of sophistication in the systems helps you build relationships and strengthens your reputation. It’s almost a necessity if you’re going to deal with the Fortune 500s on their level.”

VP of Supply Chain and Operations, Midlab

As a business grows successfully over decades, historical information from old records, outdated software, and personal relationships are patched together with new programs and processes as the business evolves. Veteran employees carry valuable experience in their heads. This patchwork creates an unstable basis for strategic business decisions. It also creates stumbling blocks to performing smoothly on a higher level. Ultimately, that’s a risk for your hard-earned reputation with loyal customers and new clients.

Efficience made sense for Midlab. They created an information infrastructure that assimilated diverse pieces of data. New and old systems were integrated. Customized programs were added that challenged the old industry standards. “Midlab was a good model for how we could work with Efficience to streamline, integrate new systems, and optimize existing resources. We are still on that journey with many successes along the way.”

Growing companies make the required investment in capital and facility expansion, but sometime overlook the information tools needed to support strategy and performance. Midlab recognized that need early. They were on a hot streak, partly due to their R&D capability to fulfill demand for more customized, “green” products. They invested heavily in capital and facility. When Matt came to MidLab in 2011, the company needed better tools to sustain success, make strategic decisions, and maximize ROI. Efficience was a natural fit for what he needed to accomplish.

“WE ALREADY KNEW WHAT EFFICIENCE COULD DO. BY THE TIME WE INTRODUCED IT EVERYONE WAS STARVED FOR IT.”

“An ordinary business person can develop solutions without being an IT expert. All you have to do is articulate your problem, then Efficience can help you define it in terms that find the solution.”

VP of Supply Chain and Operations, Midlab

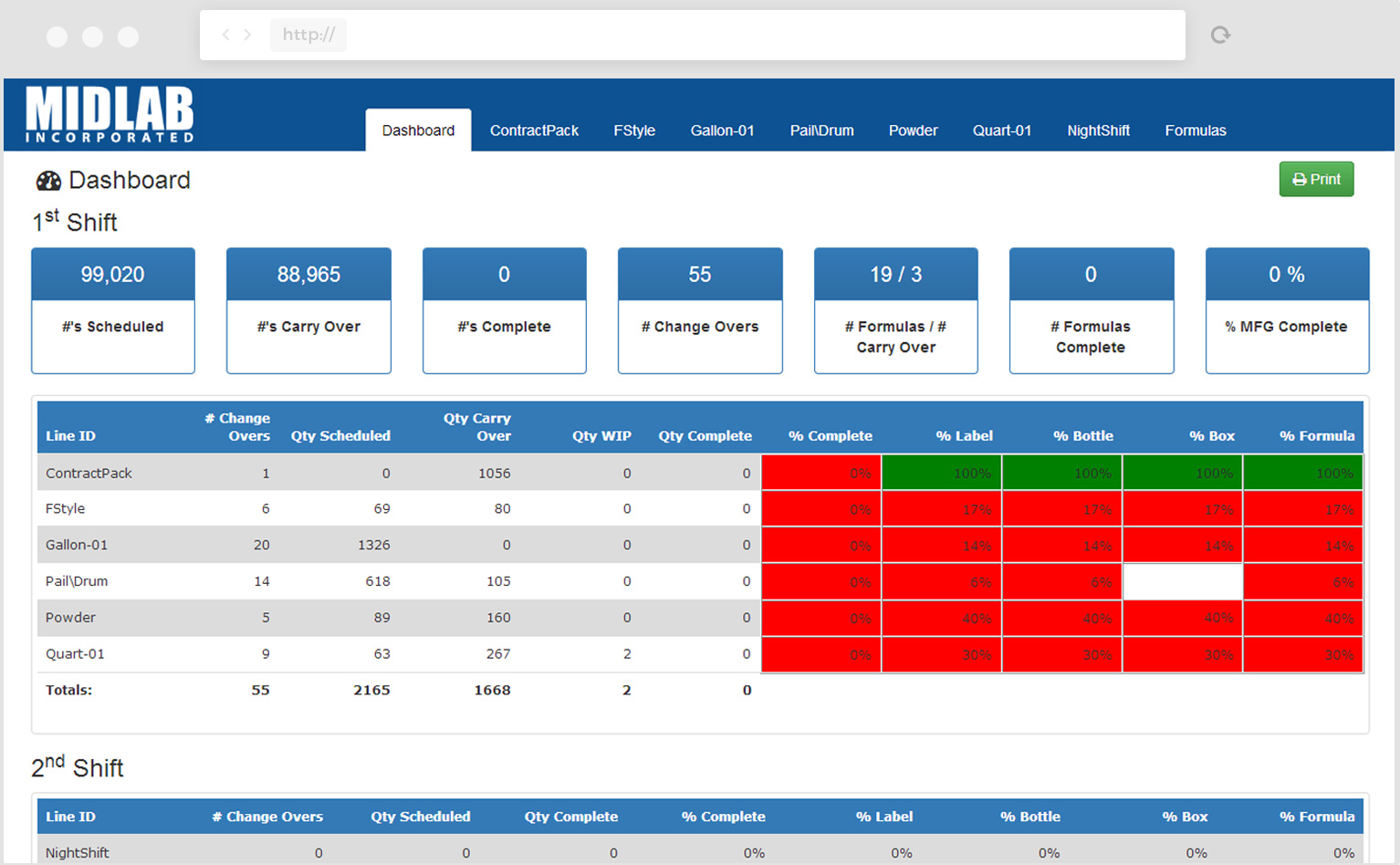

Midlab began with a Data Warehouse to store, integrate, and access all the pieces of valuable information. The Data Warehouse becomes the mega-resource for efficiency, customer service, operational improvements, and fast business decisions.

Some companies think they have a Data Warehouse – what they really have is a dumping ground. For data to be useful, information that goes into the warehouse must be scrubbed and prepared before it can be distilled. The essential elements of the business are defined in measurable IT terms. It’s somewhat like discovering the atoms and bonds that make up the molecules of each of your distinct business processes. A Warehouse makes diverse pieces fit together, within old and new programs.

To make the strategic next steps in a new competitive landscape as you scale up your business, timing is everything. “You need real-time visibility into your data. That’s where Efficience has taken us.”

Once the data warehouse is built and the units of data are prepared, you can begin to integrate. All the systems were integrated, removing interdepartmental roadblocks and speeding the information flow throughout the processes. Their customized MRP system streamlined manufacturing and production schedules. The CRM system was tied into payroll with productivity metrics.

The build-out of the ERP was a game changer. The ERP, or Enterprise Resource Planning, helps manage supply chain, inventory, and core business processes. In the old-school manufacturing world, the integration of e-commerce applications was underappreciated. Efficience expanded the capabilities of the ERP beyond typical manufacturing applications with more intuitive features for the customer and better data to inform marketing decisions. That became a competitive advantage for Midlab.

Once existing programs are smoothly integrated, the glaring gaps become obvious. That’s when you create custom programs to address problems you never knew you had. For Midlab, one new custom program provided insights into an area of sales promotion that was costing $150,000 annually, but the supporting data did not exist in the previous ERP. That one new program alone led to new steps in the sales process and smarter decisions that saved $60,000 a year.